The New Era of Construction Fleet Management

The construction world runs on heavy equipment — and every idle hour costs money. Keeping machines moving, maintained, and accounted for has always been one of a contractor’s biggest challenges. Today, that’s changing fast.

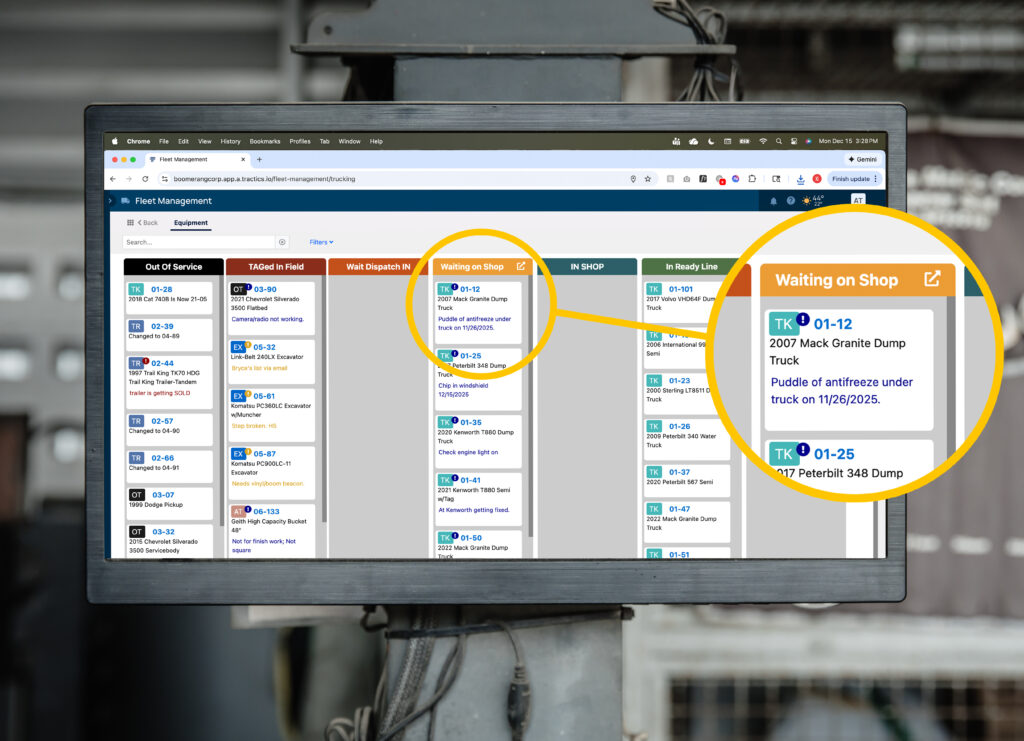

Modern construction fleet management software is reshaping how contractors operate. It gives teams visibility into every piece of equipment, whether it’s rolling down the highway or sitting on-site waiting for the next load. With data flowing in real time, you don’t have to guess where your machines are, who’s using them, or how they’re performing.

It’s not about adding more software — it’s about connecting the tools you already rely on to make smarter, faster decisions. The result? More uptime, tighter schedules, and fewer costly surprises.

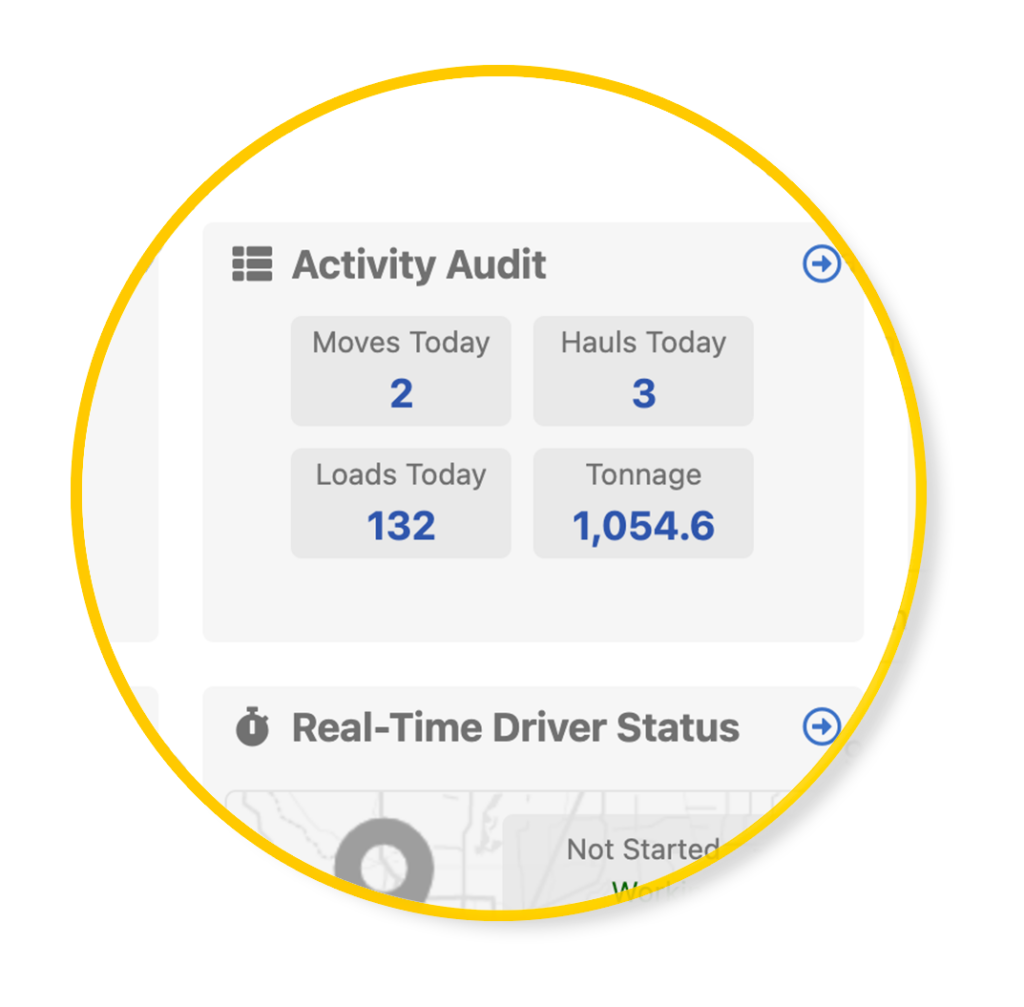

Real-Time Tracking That Keeps Projects Moving

In the past, fleet tracking meant whiteboards, phone calls, and the occasional text asking, “Where’s the loader?” Now, construction fleet tracking gives project managers the answers instantly. GPS-enabled equipment monitoring delivers precise locations and usage data across every job site.

For project managers, this visibility means no more overbooking or equipment mix-ups. For foremen, it means knowing which machines are free and which are running hot. For operators, it means less downtime and less waiting on the next assignment.

When construction equipment fleet management becomes part of your daily workflow, you can plan smarter, schedule tighter, and keep jobs on pace — without the scramble.

Simplified Maintenance for Maximum Uptime

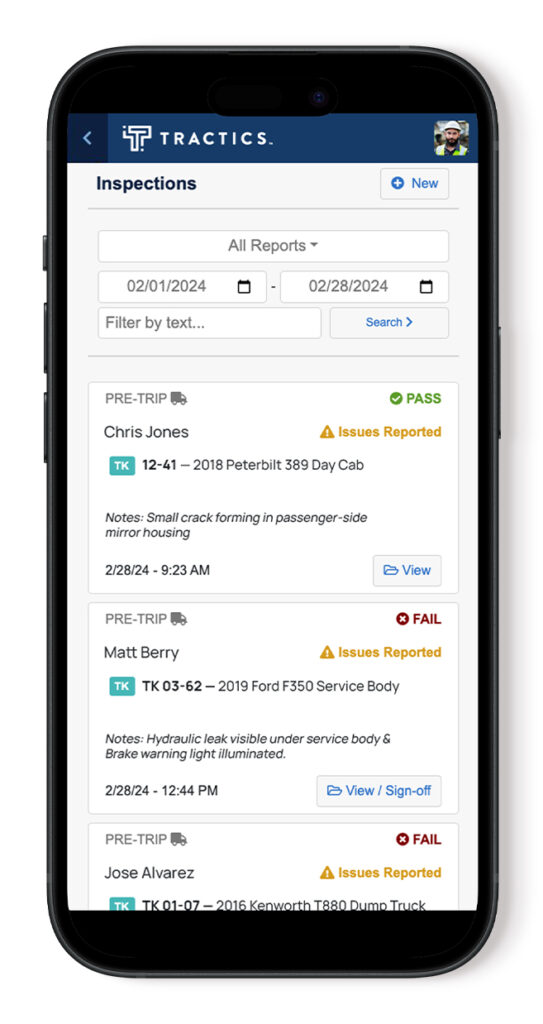

Even the best-run projects fall behind when equipment breaks down. Routine maintenance and early detection make all the difference, but manual tracking rarely keeps up. That’s where a fleet maintenance app changes the game.

Maintenance reminders, inspection logs, and service history live in one place, so you can stay ahead of breakdowns instead of reacting to them. Automated alerts flag issues before they become downtime, and your mechanics get real-time access to what’s happening on site.

Modern fleet monitoring apps go even further by combining diagnostics, utilization data, and maintenance schedules into one dashboard. It’s not just about fixing problems — it’s about preventing them. Keeping machines running means keeping projects on track and budgets under control.

This proactive approach is what separates efficient teams from the rest. Contractors who leverage these systems spend less time fighting issues and more time building.

Smarter Resource Use and Lower Costs Across Your Construction Fleet

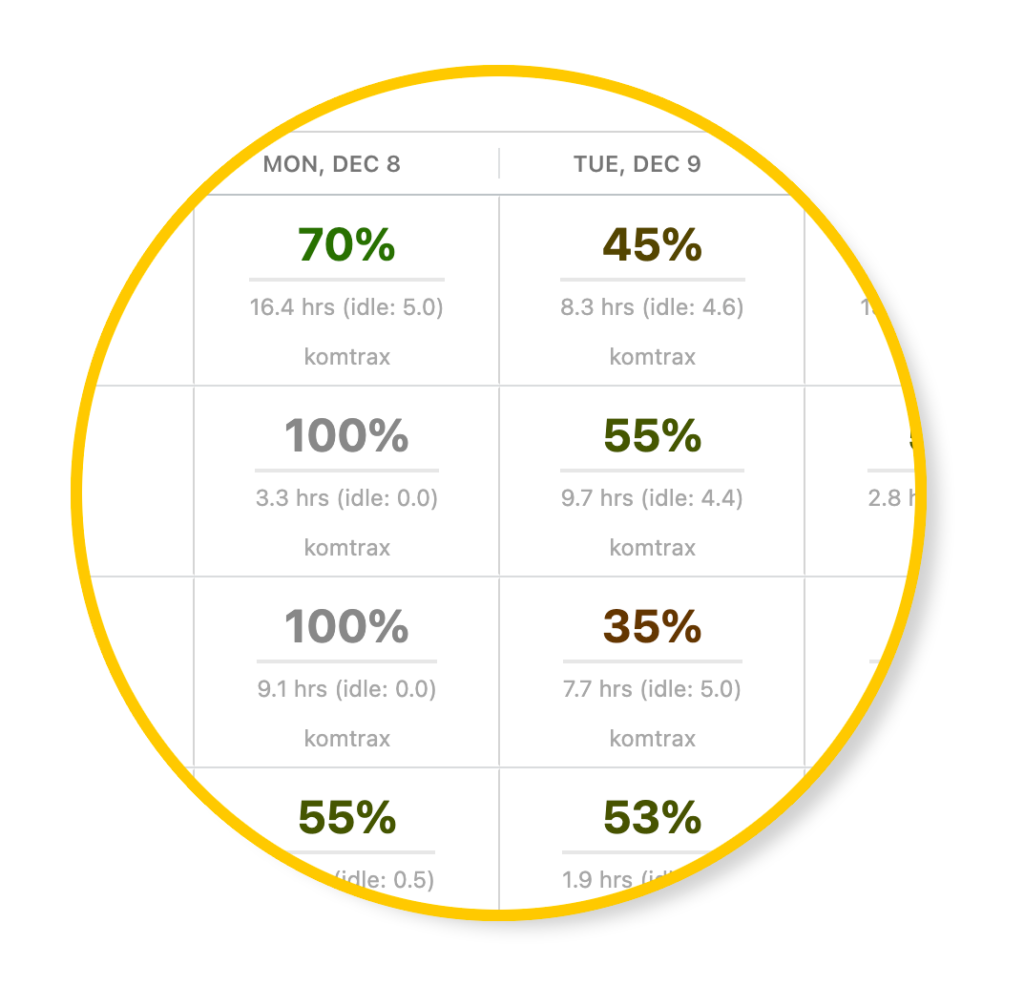

Fuel, idle time, and logistics can quietly drain profitability. The challenge is knowing where that waste is happening and how often. With connected construction fleet management tools, those hidden costs finally come into focus.

Fleet tracking analytics reveal how your machines are being used — or not used. You’ll see patterns like idling during shift changes or overlapping equipment assignments between crews. Once you see the data clearly laid out, reducing waste becomes far more straightforward.

Construction fleet tracking also makes coordination across job sites easier. Equipment can be moved or reassigned with confidence because you know exactly what’s available and where. Over time, that adds up to lower fuel bills, fewer rentals, and better utilization of the assets you already own.

These tools don’t just cut costs — they sharpen margins across the entire operation. The result is better control, better planning, and better returns from your fleet.

Building Safer, More Compliant Jobsites

Safety doesn’t stop at the crew — your fleet is part of it too. Knowing where your equipment is and how it’s being used directly impacts site safety and compliance.

Fleet monitoring apps track machine health and operator behavior in real time, helping teams prevent risky situations before they escalate. Alerts can notify you if a machine leaves its geofence, operates after hours, or needs immediate attention.

Automated logs also make compliance easier. Whether it’s service history, inspection records, or equipment certifications, everything is documented digitally and ready when needed.

The benefit isn’t just regulatory — it’s peace of mind. Safer, well-maintained equipment protects both your crew and your schedule.

Future-Proofing Construction Operations

Technology is evolving quickly, but the goal stays the same: build smarter, safer, and faster. Investing in construction equipment fleet management solutions today means setting up your business for the next generation of efficiency.

The most effective platforms don’t just track vehicles — they connect them. They link your equipment data with schedules, field updates, and job costs, creating a single source of truth across the company. For contractors, that means fewer blind spots, tighter budgets, and smoother handoffs between teams.

And when a platform feels intuitive — not complicated — adoption is easy. Crews in the field use it because it helps them work faster, not because they’re told to.

That’s the kind of connected technology built for the way construction really runs.

Build Connected. Build Confident.

Fleet management isn’t just about tracking machines — it’s about controlling what happens next. From monitoring equipment to planning maintenance and optimizing fuel spend, these tools give you the visibility and control every contractor needs to stay ahead.

When your construction fleet management system ties directly into your scheduling, project tracking, and field operations, you gain a real competitive edge — one that’s built on uptime, accuracy, and trust.

That’s the future of fleet management. And it’s already here.

– The Tractics Crew